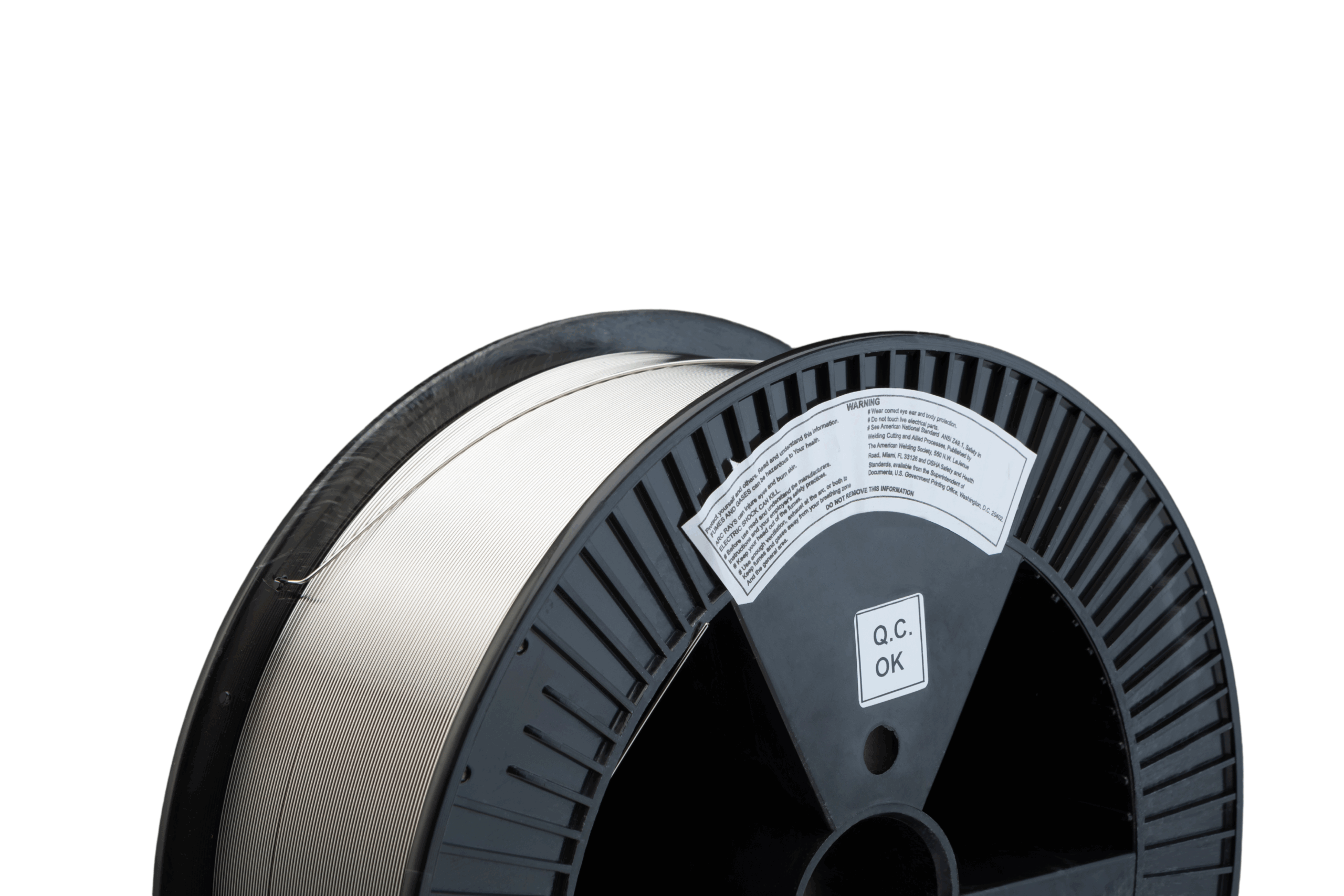

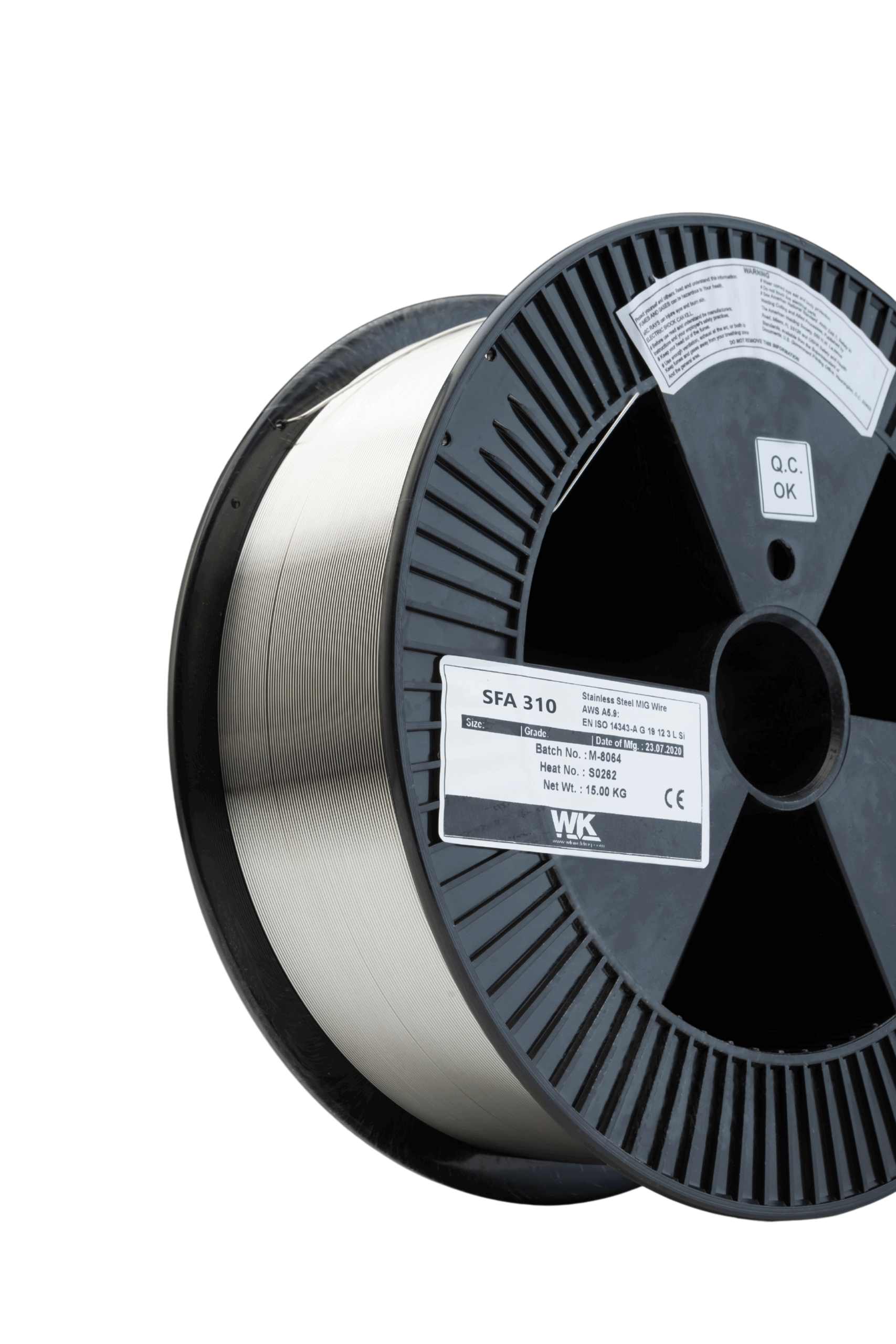

SFA 310

SFA 310 is a solid MAG welding wire ,supplied precision layer wound , depositing a C-25 Chrome, 20 Nickel weld metal suitable for use with Ar + 2% O2 or Ar + 0.5…..5% Co2 mixed shielding gases.

SFA 310 weld metal has high temperature ductility , excellent resistance to oxidation at working temperature <1100°C.

Related products

-

ITR 316LSI

ITR 316LSI is an extra low carbon 19 Cr/ 12 Ni/ 3 Mo /0.85 Si type stainless steel TIG rod similar in composition to ER 316LSi suitable for the welding or surfacing of having similar compositions.

-

SC NiFe

Graphite basic coated electrode with a Ferro-Nickel alloy deposit for joining and repairing nodular cast iron. Deposit homogeneous and highly resistant against cracks. Particularly recommended for dissimilar welding of cast iron to steels and constructions of cast iron.

-

SC 312

Electrode for high strength joint welding and surfacings of similar and equal steels or cast steels, for joint welding tensile unalloyed steels…