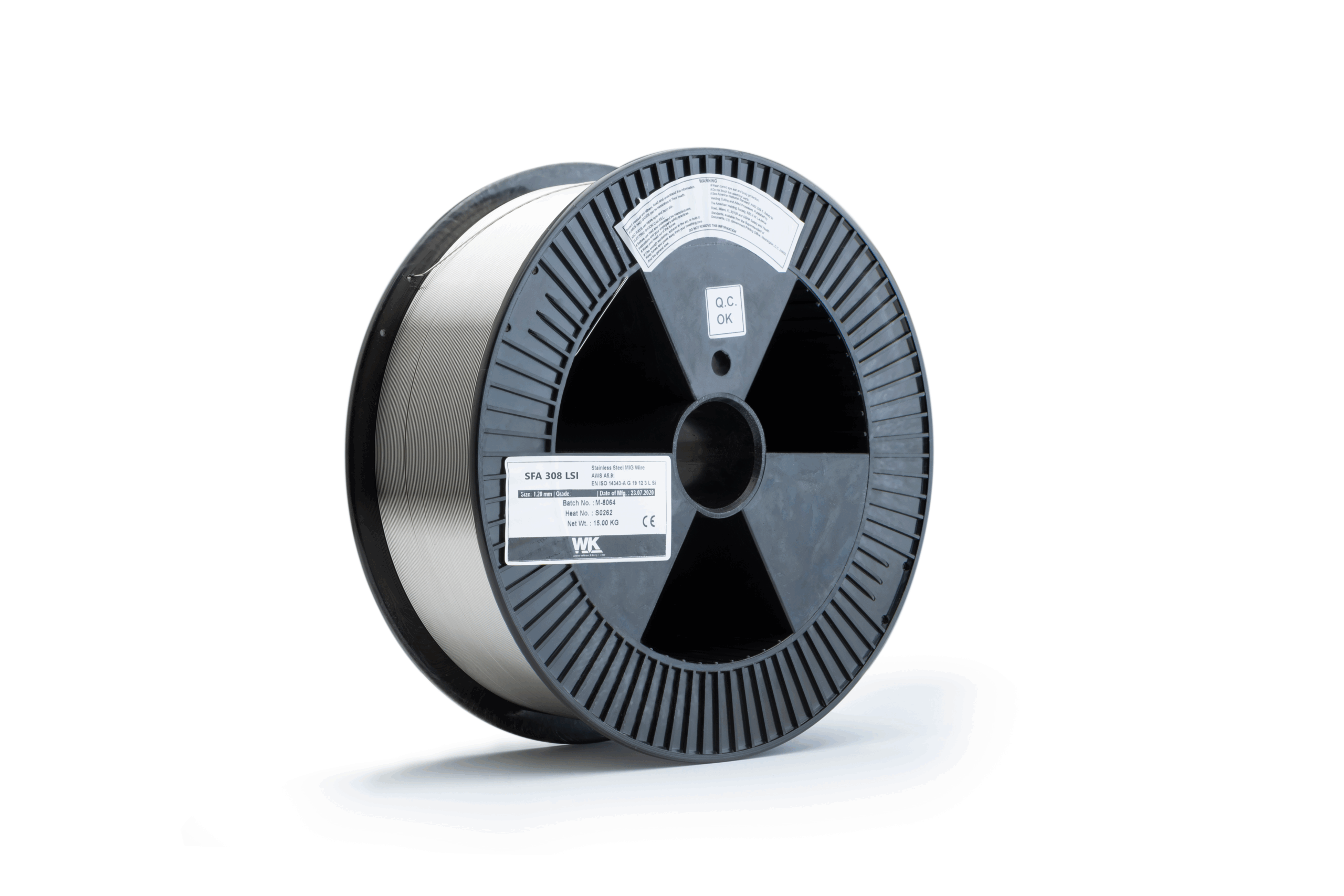

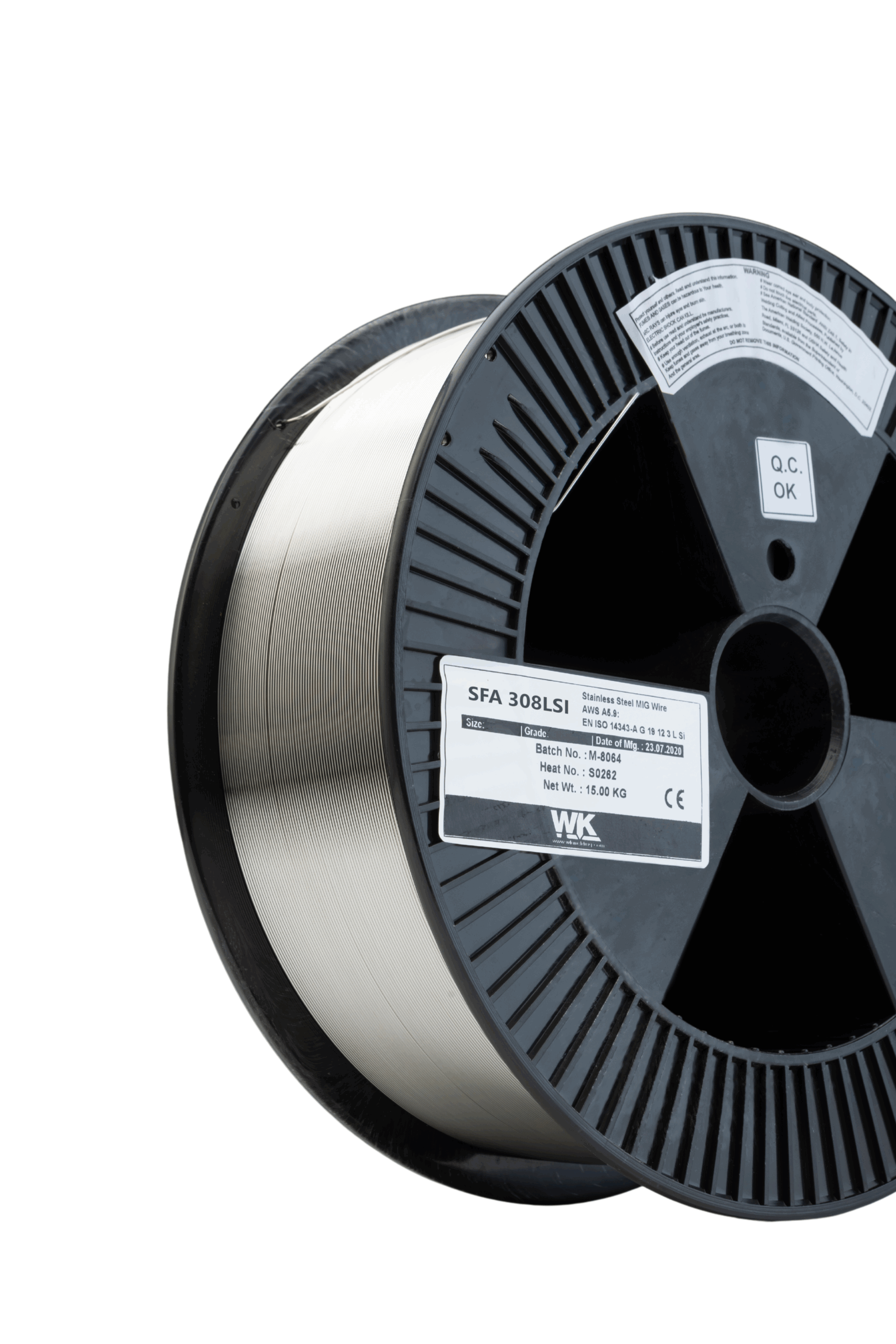

SFA 308LSI

SFA 308LSI is an extra low carbon 20 Cr/ 9 Ni stainless steel filler wire suitable for MIG welding of austenitic stainless steels such as 18 Cr /8 Ni type, AISI 301, 302, 304, 304L, 308 and 308L type of steels.

Excellent corrosion resistance and good mechanical properties. Ferrite is controlled between 5-10%.Si~0.80 content improves weldability and bead appearance.

Related products

-

ITR 316LSI

ITR 316LSI is an extra low carbon 19 Cr/ 12 Ni/ 3 Mo /0.85 Si type stainless steel TIG rod similar in composition to ER 316LSi suitable for the welding or surfacing of having similar compositions.

-

SC 308L-17

Low carbon Rutile-silica-coated 19Cr, 10Ni austenitic stainless steel electrode with controlled ferrite approx 6-8% for maximum resistance to cracking and corrosion. Core wire is 308LER.

-

ITR 308L

ITR 308L is a 20 Cr / 10 Ni stainless steel TIG welding wire similar in composition to ER 308L, suitable for welding of austenitic stainless steels such as 18 Cr/ 8 Ni type, AISI 304, 304L, 308 and 308L type of steels.