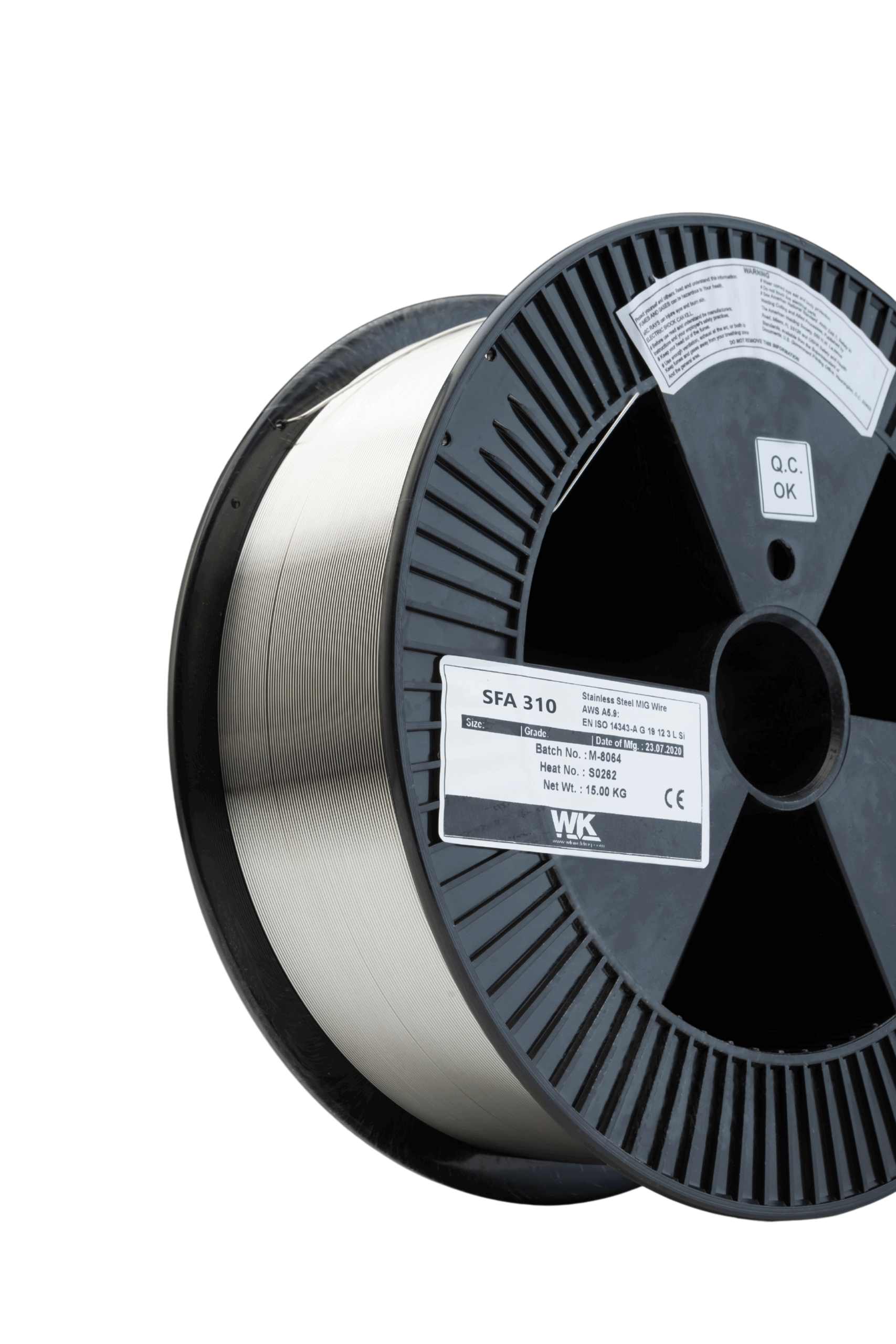

SFA 310

SFA 310 is a solid MAG welding wire ,supplied precision layer wound , depositing a C-25 Chrome, 20 Nickel weld metal suitable for use with Ar + 2% O2 or Ar + 0.5…..5% Co2 mixed shielding gases.

SFA 310 weld metal has high temperature ductility , excellent resistance to oxidation at working temperature <1100°C.

Related products

-

ITR 309LSI

ITR 309LSI is a stainless TIG rod conforming to ER 309LSi for welding austenitic stainless steels such as AISI 309LSi.

-

SC 6010

Cellulosic coated deep penetration electrode for welding of pipes and pipelines in all positions using conventional and stove pipe techniques.

-

SFA T-50

Flux cored wire for all positions with excellent weldability characteristics. The SFA-T50 leaves a welding bead perfectly flat and with low spatter level. Designed for single-pass or multi-pass, the slag is easily removed and is prepared for use with Ar / CO2 (20-25%) or CO2 gas. It has excellent results in low temperature impact tests.

It is a flux cored wire of great efficiency thanks to its high deposition rate.

Extremely versatile for a wide variety of applications, such as shipbuilding, storage tanks, bridges and general fabrication of structural steels.