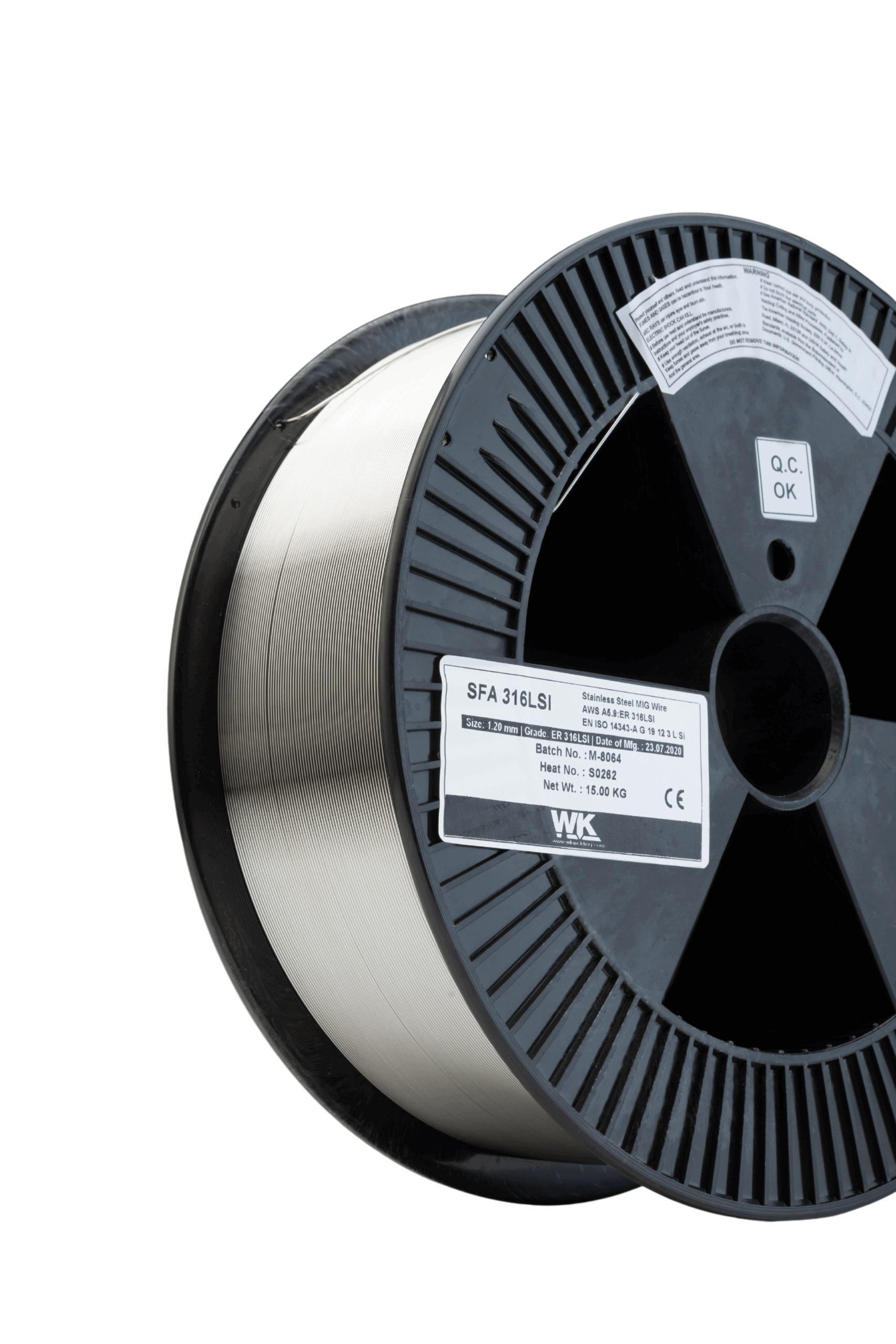

SFA 316LSI

SFA 316LSI is a G 19 12 3 LSi/ER 316LSi type solid MAG welding wire, supplied precision layer wound, depositing a low C-19Cr12Ni2.5Mo weld metal. Suitable for use with Ar+2%O2 or Ar+0.5…5%CO2 mixed shielding gases.

SFA 316LSI is used for welding of 316 and 316L grade stainless steels, in a wide range of applications including the fabrication of pipe and plate.

Related products

-

SC 312

Electrode for high strength joint welding and surfacings of similar and equal steels or cast steels, for joint welding tensile unalloyed steels…

-

SC 316L

Low carbon Rutile-basic-coated Mo containing austenitic stainless steel electrode with approx 5-9% ferrite. Coating with very low moisture pick-up.

-

ITR 308L

ITR 308L is a 20 Cr / 10 Ni stainless steel TIG welding wire similar in composition to ER 308L, suitable for welding of austenitic stainless steels such as 18 Cr/ 8 Ni type, AISI 304, 304L, 308 and 308L type of steels.