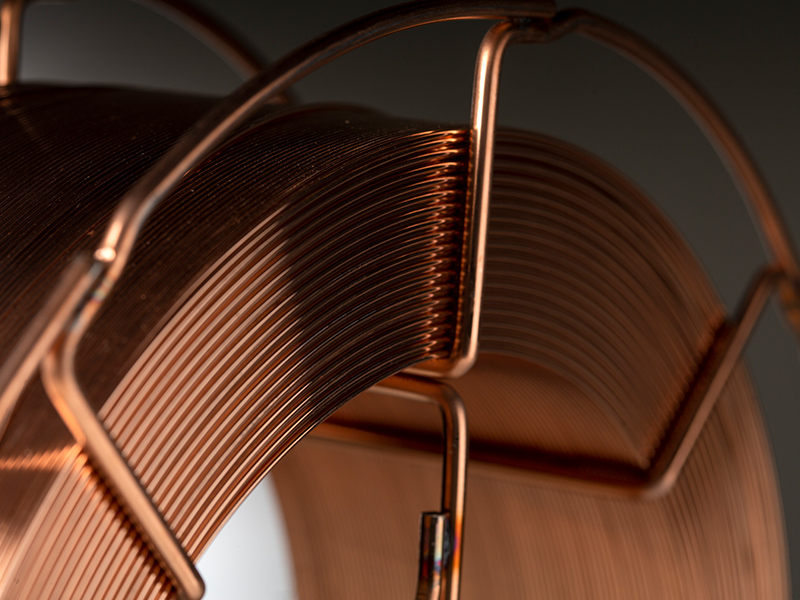

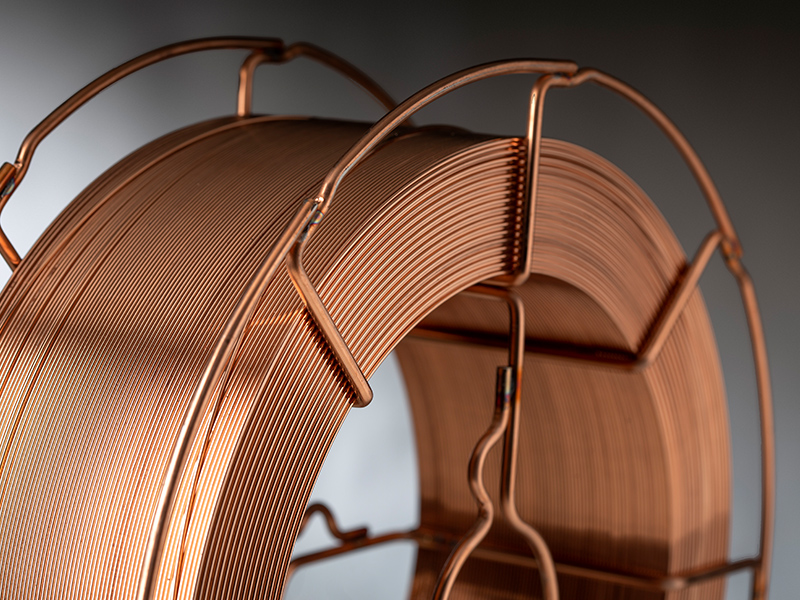

SFA 100

It is a low alloy steel wire, coated with copper, for MIG / MAG (GMAW) welding of high strength steel that requires, for critical applications, a tenacious welding metal. It is also suitable for the welding of steels to which a high resistance to impact at low temperatures is required. The SFA-100 normally uses gas mixture M21 – M33 and CO2 as a shield gas.

It is a low alloy steel wire, coated with copper, for MIG / MAG (GMAW) welding of high strength steel that requires, for critical applications, a tenacious welding metal.

![]() Download technical sheet

Download technical sheet

Related products

-

SC 6013)

Rutile type medium coated electrode, used for the welding of large structures and process pipe work in the shipbuilding and construction industries where precise fit-ups are difficult to achieve.

-

SC 308L-17

Low carbon Rutile-silica-coated 19Cr, 10Ni austenitic stainless steel electrode with controlled ferrite approx 6-8% for maximum resistance to cracking and corrosion. Core wire is 308LER.

-

ITR 312

ITR 312 is a stainless TIG rod suitable for welding or surfacing difficult to weld steels. Suitable for welding buffer layers.