-

SC 312

Electrode for high strength joint welding and surfacings of similar and equal steels or cast steels, for joint welding tensile unalloyed steels…

-

SC 316L

Low carbon Rutile-basic-coated Mo containing austenitic stainless steel electrode with approx 5-9% ferrite. Coating with very low moisture pick-up.

-

SC 6010

Cellulosic coated deep penetration electrode for welding of pipes and pipelines in all positions using conventional and stove pipe techniques.

-

SC 6013)

Rutile type medium coated electrode, used for the welding of large structures and process pipe work in the shipbuilding and construction industries where precise fit-ups are difficult to achieve.

-

SC 7016

Basic coated, low hydrogen electrode for producing tough and crack-free welded joints. Good operating characteristics when positional welding.

-

SC 7018 H4R

Basic heavy coated, iron powder, low hydrogen LMA type electrode for producing tough and crack-free welded joints even on steels having a carbon content up to 0.40%.

-

SC 7024

High efficiency, Iron powder electrode designed for outstanding deposition rates. Deposition efficiency is approximately 140—150 % .Excellent arc stability, soft fusion, fine ripples, self releasing slag, very low spatter.

-

SC NiFe

Graphite basic coated electrode with a Ferro-Nickel alloy deposit for joining and repairing nodular cast iron. Deposit homogeneous and highly resistant against cracks. Particularly recommended for dissimilar welding of cast iron to steels and constructions of cast iron.

-

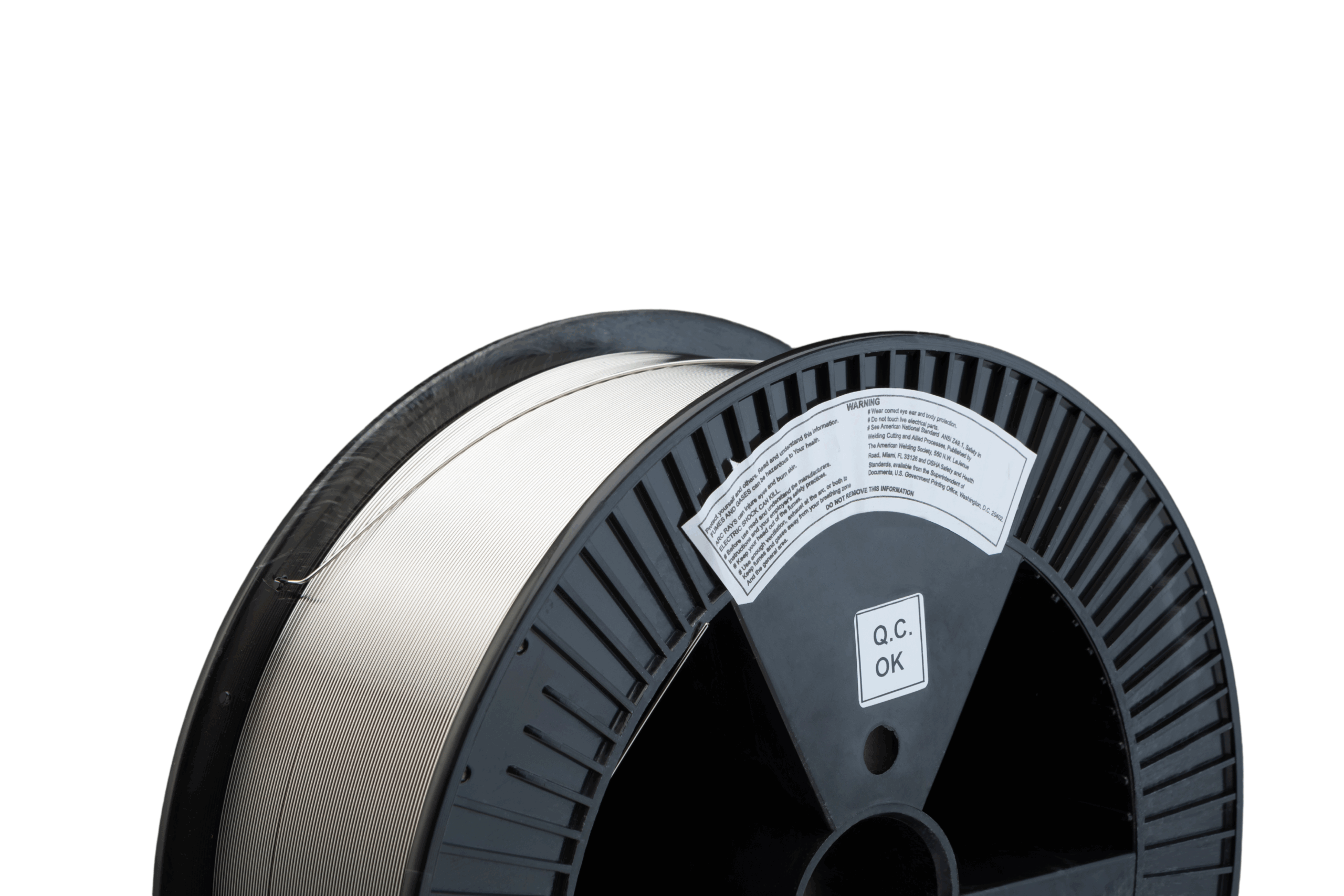

SFA 1

Solid wire SG2 indicated for MIG / MAG wire for welded mechanical constructions in general.

For welding of steels up to 530N / mm2 of minimum tensile strength.

Winding layer by layer.

It uses CO2 or Argon / CO2 mixtures as protective gas.

The welding current to be welded will always be DC current (+). -

SFA 100

It is a low alloy steel wire, coated with copper, for MIG / MAG (GMAW) welding of high strength steel that requires, for critical applications, a tenacious welding metal. It is also suitable for the welding of steels to which a high resistance to impact at low temperatures is required. The SFA-100 normally uses gas mixture M21 – M33 and CO2 as a shield gas.

-

SFA 2

– Steel construction and machinery production

– Welding of ships, boiler tanks, pipe parts

– Welding of thin walled steels. -

SFA 307

SFA 307 is a G 18 8 Mn/ER 307 (similar) type solid MAG welding wire, supplied precision layer wound, depositing a C-18Cr8Ni6Mn weld metal. Suitable for use with Ar+2%O2 or Ar+0.5…5%CO2 mixed shielding gases.