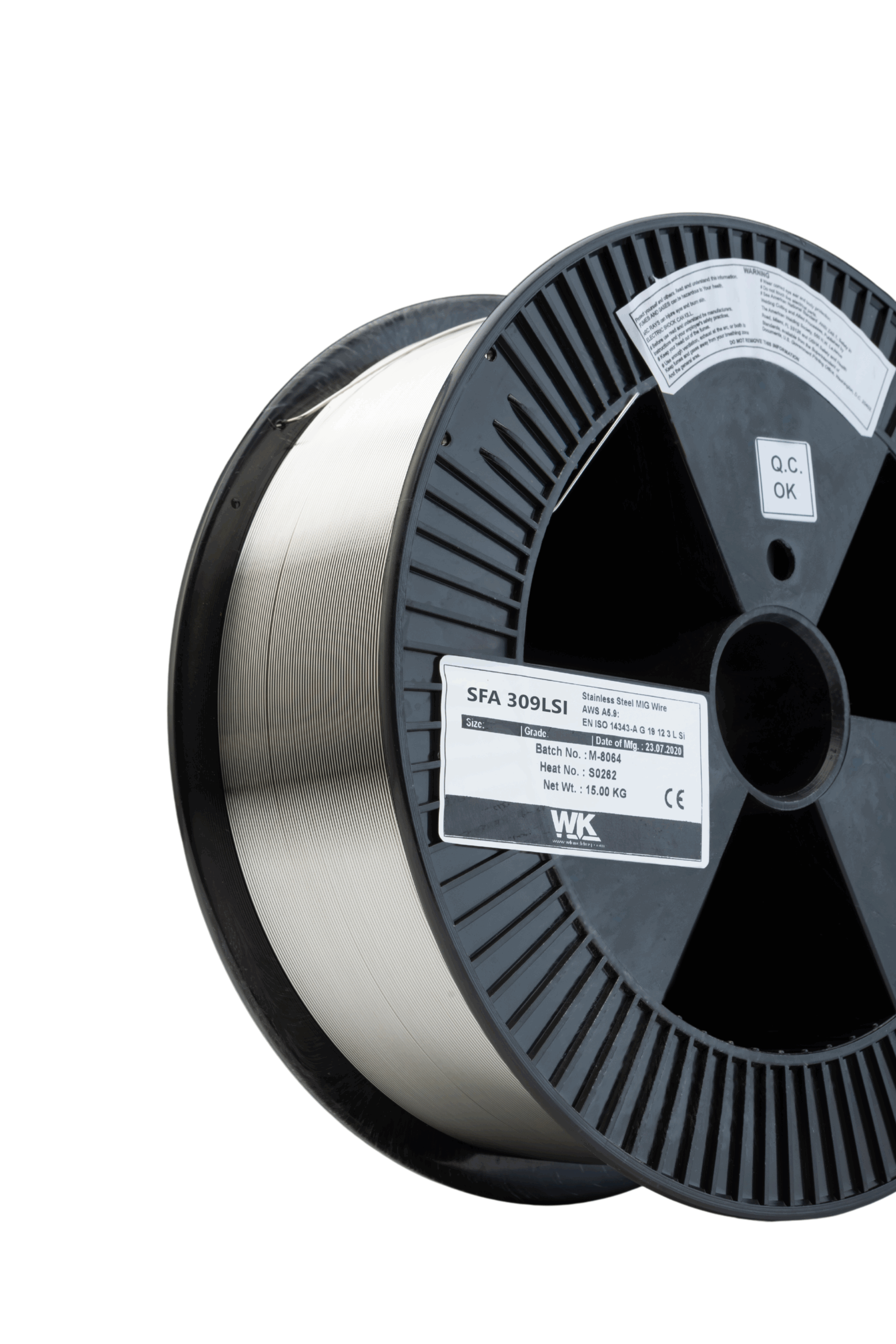

SFA 309LSI

SFA 309LSI is a G 23 12 LSi/ER 309LSi type solid MAG welding wire, supplied precision layer wound, depositing a low C-23Cr12Ni weld metal. Suitable for use with Ar+2%O2 or Ar+0.5…5%CO2 mixed shielding gases.

SFA 309LSi is used for the welding of stainless steels to mild and medium tensile steels.

Related products

-

SC 312

Electrode for high strength joint welding and surfacings of similar and equal steels or cast steels, for joint welding tensile unalloyed steels…

-

SC 308L-17

Low carbon Rutile-silica-coated 19Cr, 10Ni austenitic stainless steel electrode with controlled ferrite approx 6-8% for maximum resistance to cracking and corrosion. Core wire is 308LER.

-

ITR 316L

ITR 316L is an extra low carbon 19 Cr/ 12 Ni/ 3 Mo type stainless steel TIG rod similar in composition to ER 316L. Suitable for the welding or surfacing of having similar compositions.